In today’s fast-growing industrial world, automation plays a key role in improving productivity, safety, and operational efficiency. Factories, power plants, water treatment facilities, oil & gas industries, and manufacturing units rely heavily on automated systems to control machines and processes accurately. One important component that makes this automation possible is the digital output module.

Digital output modules are widely used in an industrial control system to control devices such as motors, relays, solenoid valves, alarms, indicators, and other industrial equipment. They act as the bridge between control logic (PLC, DCS, or controller) and real-world output devices. In this blog, we will explore what digital output modules are, how they work, and most importantly, the benefits of using digital output modules in industrial control systems.

What Are Digital Output Modules?

Digital output modules are electronic devices used in industrial automation to send ON/OFF signals from a controller to field devices. These signals help control various machines and processes in an industrial environment.

Unlike analog output modules, which provide variable signals, digital output modules work with binary signals:

- ON (1)

- OFF (0)

For example, when a PLC sends a command to start a motor, the digital output module converts that command into an electrical signal that switches the motor ON.

Role of Digital Output Modules in Industrial Control Systems

An industrial control system consists of several components such as PLCs, sensors, input modules, output modules, HMIs, and industrial equipment. Digital output modules play a crucial role by:

- Executing control commands

- Switching devices ON or OFF

- Activating alarms and indicators

- Controlling actuators and relays

- Ensuring smooth operation of automated processes

Without digital output modules, the control logic created in a PLC or controller cannot interact with real machines.

How Digital Output Modules Work

The working principle of digital output modules is simple:

- The controller (PLC or DCS) processes data from sensors and logic programs.

- Based on the program, it sends a command to the digital output module.

- The digital output module converts the command into an electrical signal.

- The signal activates or deactivates connected industrial equipment.

This process happens in milliseconds, ensuring fast and reliable control in industrial automation systems.

Types of Digital Output Modules

Digital output modules come in different types based on application requirements:

1. Relay Output Modules

- Use electromechanical relays

- Suitable for high voltage and current applications

- Provide electrical isolation

2. Transistor Output Modules

- Faster switching speed

- Ideal for high-speed automation

- Used for low-power DC loads

3. Triac Output Modules

- Used mainly for AC loads

- Common in lighting and heating control systems

Choosing the right type depends on the nature of industrial equipment and the industrial control system design.

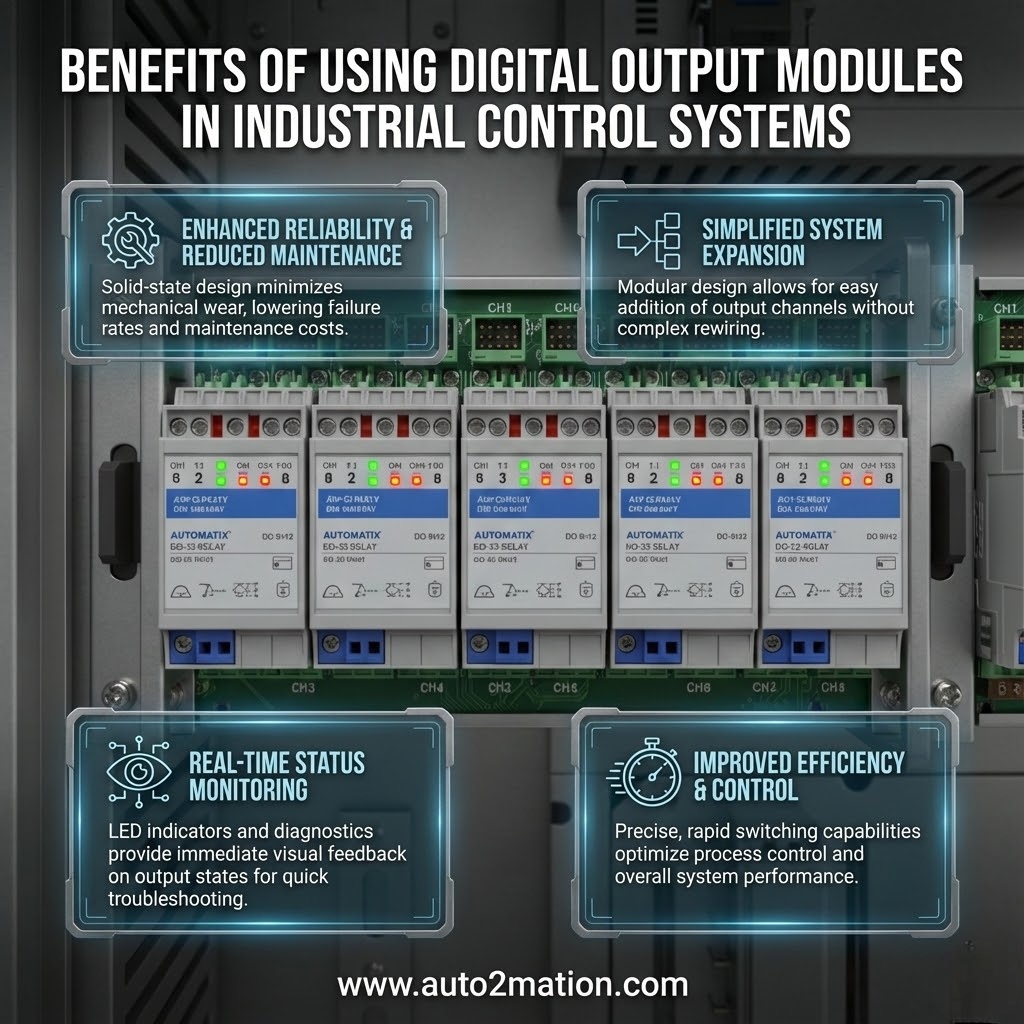

Key Benefits of Using Digital Output Modules

1. Reliable Control of Industrial Equipment

One of the biggest benefits of digital output modules is their reliability. They provide accurate ON/OFF control, which is essential for machines, motors, valves, and alarms. Reliable switching ensures smooth operation and reduces unexpected downtime.

In industrial automation, even a small error can lead to production losses. Digital output modules help maintain consistency and precision in operations.

2. Easy Integration with Industrial Control Systems

Digital output modules are designed to work seamlessly with PLCs, DCS systems, and other controllers. They can be easily integrated into existing industrial control systems without complex modifications.

This makes them ideal for:

- New automation projects

- System upgrades

- Expansion of existing industrial equipment

3. Improved System Efficiency

Automation systems using digital output modules operate faster and more efficiently than manual systems. Tasks that once required human intervention can now be controlled automatically with precise timing.

This improves:

- Production speed

- Energy efficiency

- Process accuracy

Overall system performance

4. Enhanced Safety in Industrial Automation

Safety is a top priority in any industrial environment. Digital output modules help improve safety by enabling automatic shutdowns, alarms, and emergency controls.

For example:

- Turning OFF motors during faults

- Activating warning lights or buzzers

- Controlling emergency stop circuits

These features reduce the risk of accidents and protect both workers and industrial equipment.

5. Reduced Wiring Complexity

Traditional control systems required extensive wiring, which increased installation time and maintenance effort. Digital output modules significantly reduce wiring complexity by centralizing control.

Benefits include:

- Cleaner control panels

- Faster installation

- Easier troubleshooting

- Lower maintenance costs

This is especially useful in large industrial automation projects.

6. High Switching Speed and Accuracy

Digital output modules operate at high speeds, allowing precise control of fast-moving processes. This is essential in applications such as packaging, robotics, conveyor systems, and automated assembly lines.

Accurate switching ensures that machines respond exactly when required, improving product quality and consistency.

7. Scalability and Flexibility

Industrial processes evolve over time. Digital output modules allow easy system expansion without redesigning the entire control architecture.

You can:

- Add more modules as needed

- Upgrade industrial equipment

- Modify control logic easily

This scalability makes them a cost-effective solution for growing industrial automation systems.

8. Electrical Isolation and Protection

Many digital output modules provide built-in electrical isolation between control logic and field devices. This protects sensitive controllers from voltage spikes, short circuits, and electrical noise.

- Protection features help:

- Increase system lifespan

- Prevent controller damage

- Reduce maintenance issues

9. Better Monitoring and Diagnostics

Modern digital output modules often include LED indicators and diagnostic features. These allow technicians to quickly identify the status of outputs and troubleshoot problems.

Better diagnostics mean:

- Faster fault detection

- Reduced downtime

- Improved system reliability

Applications of Digital Output Modules in Industrial Automation

Digital output modules are used across various industries and applications, including:

- Manufacturing plants

- Power generation and distribution

- Water and wastewater treatment

- Oil and gas industries

- Food and beverage processing

- Pharmaceutical production

- Material handling systems

- Building automation systems

In each application, they play a vital role in controlling industrial equipment safely and efficiently.

Importance of Digital Output Modules in Modern Industry

As industries move toward smart factories and Industry 4.0, the importance of digital output modules continues to grow. They form a critical link between digital control systems and physical processes.

With increasing demand for automation, accuracy, and safety, digital output modules are becoming essential components of every industrial control system.

Choosing the Right Digital Output Module

When selecting a digital output module, consider the following factors:

- Voltage and current ratings

- Type of load (AC or DC)

- Switching speed requirements

- Environmental conditions

- Compatibility with controllers

- Safety and isolation features

Choosing the right module ensures optimal performance and long-term reliability.

Future of Digital Output Modules in Industrial Automation

With advancements in technology, digital output modules are becoming smarter and more efficient. Future developments include:

- Improved diagnostics

- Better communication capabilities

- Compact designs

- Enhanced energy efficiency

- Integration with IoT systems

These improvements will further strengthen their role in modern industrial automation systems.

Digital output modules are a vital part of any industrial control system. They provide reliable, safe, and efficient control of industrial equipment, making automation possible across various industries.

From reducing wiring complexity and improving safety to enhancing system efficiency and scalability, the benefits of using digital output modules are clear. As industrial automation continues to evolve, these modules will remain essential for building smart, efficient, and reliable control systems.

Investing in quality digital output modules not only improves current operations but also prepares industrial facilities for future automation needs.