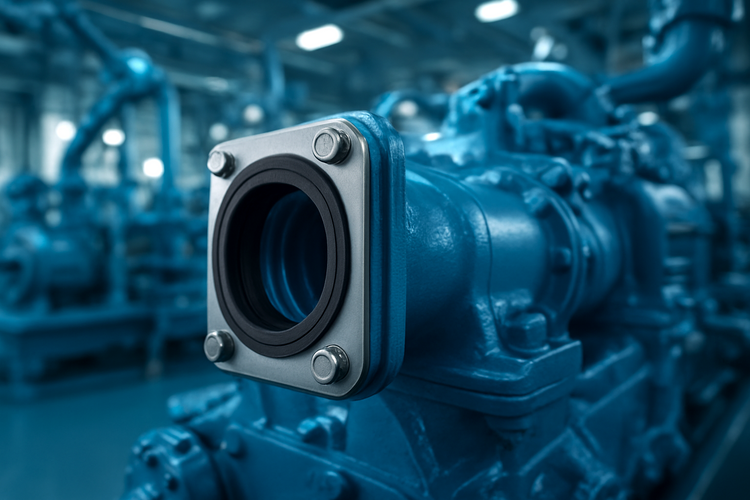

Marine industries depend on equipment that operates under extreme conditions. Engines, pumps, compressors, and pipelines in marine environments are constantly exposed to heat, vibration, high pressure, and saltwater. To keep these systems working efficiently and safely, every component must perform at its best. One small part that plays a massive role in this reliability is the marine gasket.

While gaskets may look simple, they are critical in sealing joints, preventing leakage, and ensuring smooth operation. Using high-quality marine gaskets is essential because low-quality or worn-out gaskets can lead to system failures, costly repairs, and downtime. This blog explains the importance, applications, and major benefits of using high-quality marine gaskets.

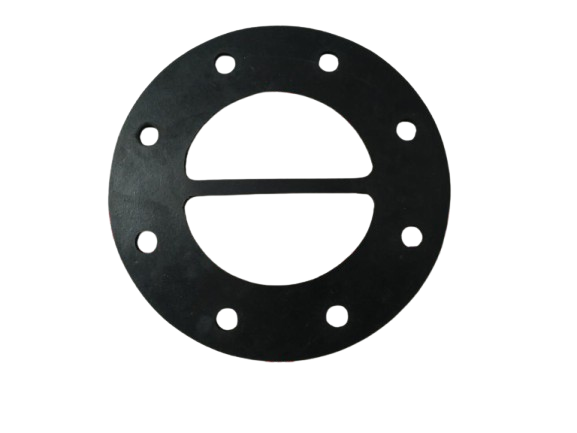

What are Marine Gaskets?

A marine gasket is a sealing material placed between two surfaces to prevent leaks of gases, fluids, or contaminants. They are widely used in marine engines, pipelines, pumps, exhaust systems, compressors, and other onboard machinery.

Marine gaskets are typically made from specialized materials such as:

- Rubber compounds like neoprene, nitrile, or EPDM

- Compressed non-asbestos fiber (CNAF)

- Graphite

- Metallic gaskets such as spiral wound or ring joint

- PTFE (Teflon)

Each material is designed to handle specific pressures, temperatures, and chemical exposures common in marine environments.

Why Quality Matters in Marine Gaskets

In the marine industry, equipment failure is not just exclusive—it can also be dangerous. Leaks in fuel lines, exhaust systems, or hydraulic systems can cause fires, pollution, or breakdowns at sea. Choosing high-quality marine gaskets ensures long-term performance, safety, and efficiency.

Unlike generic or low-grade gaskets, marine-grade gaskets are:

- Tested for durability under high pressure and vibration

- Resistant to saltwater corrosion

- Designed to handle extreme temperatures

Key Benefits of Using High-Quality Marine Gaskets

1. Superior Sealing Performance

The main role of a gasket is to provide a tight seal. High-quality gaskets ensure complete sealing even under fluctuating loads, high temperatures, and vibrations. This minimizes the chances of leaks in fuel, oil, coolant, or exhaust systems.

2. Prevents Leakage and Contamination

Leaks in marine equipment can cause operational issues, safety risks, and environmental damage. A good gasket prevents oil, fuel, or water leaks, protecting both the crew and the environment from hazardous spills.

3. Enhances Engine and Equipment Efficiency

Engines and pumps run more smoothly when there are no leaks or pressure drops. High-quality marine gaskets maintain the correct pressure levels, which helps equipment operate at maximum efficiency.

4. Resistant to Harsh Marine Conditions

Marine environments are challenging due to saltwater, high humidity, and constant vibrations. High-quality gaskets are specifically engineered to resist corrosion, swelling, and deterioration caused by seawater exposure.

5. Improves Safety Onboard

Leaks in fuel or exhaust systems can cause fires or harmful gas exposure. Using reliable gaskets ensures crew safety by preventing dangerous leaks. Safety regulations also demand the use of quality sealing materials.

6. Reduces Maintenance Costs

Replacing low-quality gaskets frequently is costly. A durable gasket lasts longer, reducing the frequency of replacements and saving both time and money.

7. Minimizes Downtime

Equipment downtime at sea can lead to delays, financial loss, and safety issues. High-quality gaskets provide long-term reliability, ensuring machinery continues to run without unexpected failures.

8. Eco-Friendly Operation

Leaks from marine machinery often led to oil spills or gas emissions that harm marine life. High-quality gaskets prevent such leaks, making marine operations more environmentally friendly.

9. Better Tolerance to High Pressure

Marine engines and exhaust systems operate under extreme heat and pressure. High-quality gaskets maintain their shape and sealing properties even in the toughest conditions.

10. Compliance with Industry Standards

Marine equipment must follow strict international safety and quality standards. High-quality gaskets are manufactured to meet these certifications, ensuring compliance with global regulations.

Applications of Marine Gaskets

High-quality gaskets are used across a wide range of marine systems:

- Engines: Cylinder head gaskets, exhaust gaskets, and oil seals.

- Pipelines: Sealing joints in fuel, oil, and water pipelines.

- Pumps & Compressors: Preventing leaks in high-pressure systems.

- Exhaust Systems: Sealing joints to prevent gas leaks.

- Hydraulic Systems: Maintaining pressure without leaks.

- Heat Exchangers: Ensuring efficient transfer of heat without fluid leakage.

Long-Term Benefits of Choosing the Right Gasket

When marine operators choose high-quality gaskets, they invest in long-term savings and reliability. Benefits include:

- Extended equipment lifespan – Reduced wear and tear.

- Fewer emergency repairs – Prevention of breakdowns at sea.

- Stable operations – Consistent performance of engines and pumps.

- Improved productivity – Less downtime and smoother voyages.

Why Marine Operators Prefer High-Quality Gaskets

Marine operators choose high-quality gaskets because they:

- Protect crew safety.

- Ensure regulatory compliance.

- Reduce operational risks.

- Provide long-term savings.

High-quality marine gaskets are small but vital components that ensure the safe, efficient, and reliable operation of marine machinery. They provide superior sealing, resist harsh marine conditions, prevent leaks, and extend equipment lifespan. By investing in durable and certified gaskets, marine operators can reduce downtime, save on maintenance costs, protect the environment, and ensure compliance with international safety standards.