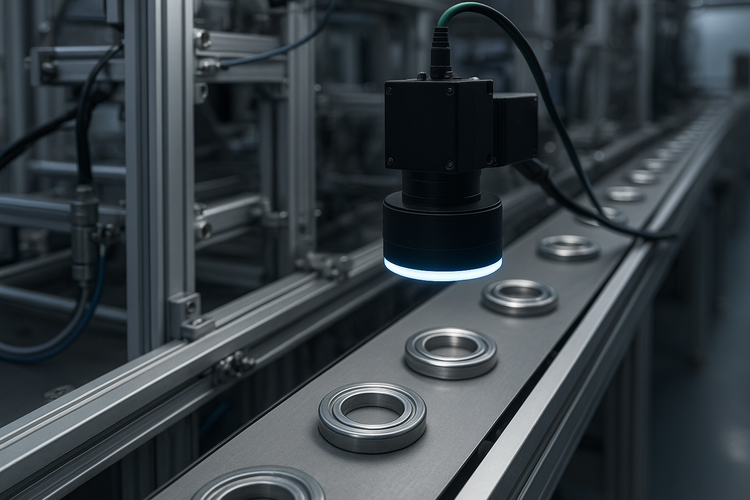

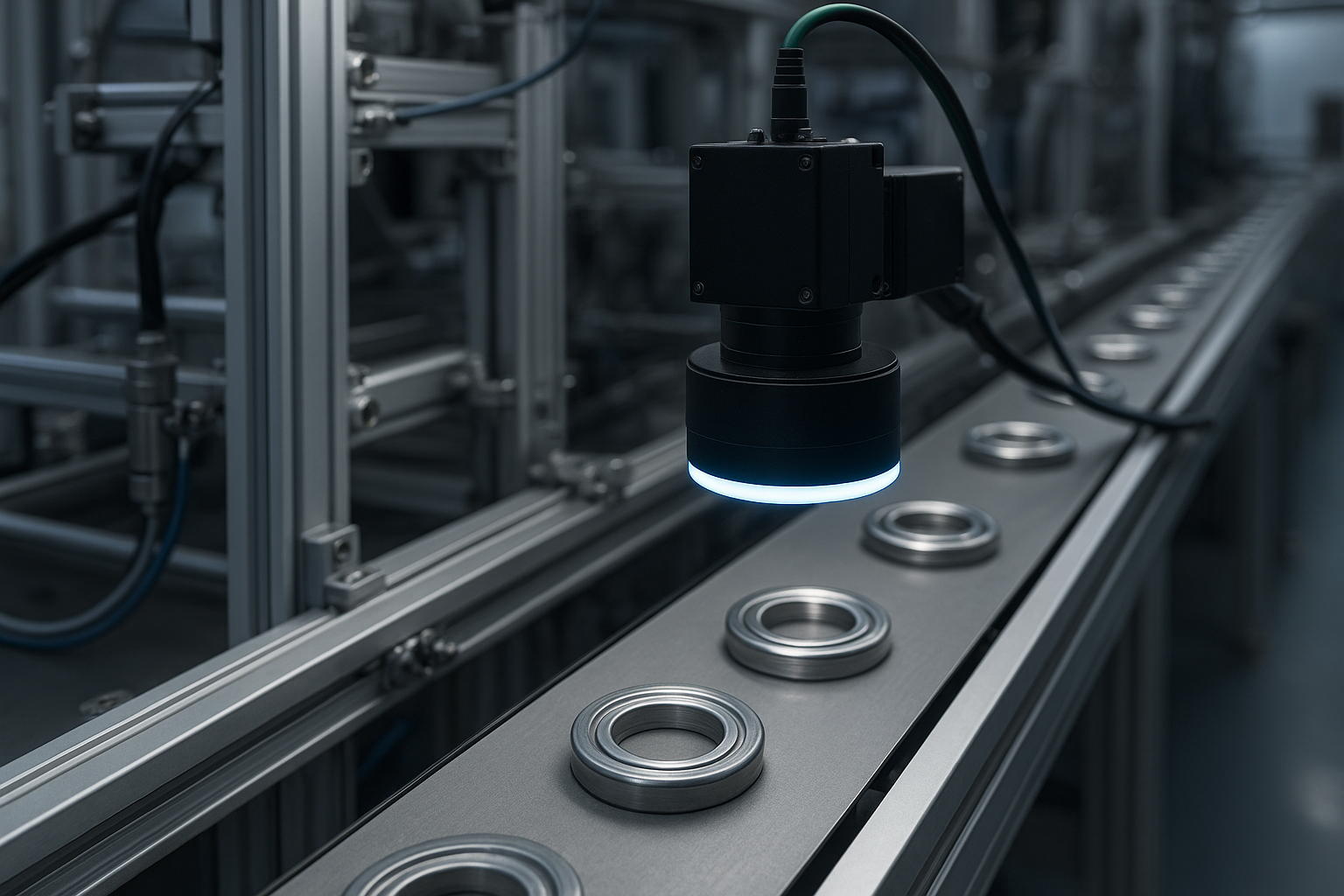

In today’s competitive manufacturing world, businesses are always looking for ways to improve quality, reduce costs, and increase productivity. One of the most powerful tools that helps achieve these goals is a vision inspection system. These systems use cameras, sensors, and image processing software to inspect products in real-time during the production process. From checking the quality of a car part to inspecting printed circuit boards, vision inspection systems have become a crucial part of modern manufacturing automation. They not only help in catching defects early but also speed up the entire production line, ensuring consistent product quality and higher efficiency.

What Is a Vision Inspection System?

A vision inspection system is a technology that uses one or more high-resolution cameras, combined with smart software, to inspect and analyze products. These systems can check shape, size, color, texture, alignment, surface defects, and other critical parameters.

The system works by capturing images of products as they move through the production line. The software then analyzes these images and compares them with preset standards. If a product does not meet the required specifications, it is flagged or removed from the line automatically.

Key Benefits of Vision Inspection Systems

1. Increased Productivity

By automating the inspection process, vision systems work much faster than manual inspections. They can inspect hundreds or even thousands of parts per minute. This helps in maintaining a steady production flow without delays.

2. Higher Accuracy

Human error is common in manual inspections. Vision inspection systems deliver consistent and highly accurate results. They can detect the smallest of defects that might be missed by the human eye.

3. Real-Time Quality Control

With vision systems, quality control happens in real time. Products are inspected as they are made, helping catch defects early and reducing waste. This leads to better product quality and less rework.

4. Lower Labor Costs

Vision inspection systems reduce the need for large inspection teams. One system can do the work of several human inspectors. This not only saves money but also frees up human workers for more valuable tasks.

5. Data Collection and Reporting

Modern vision systems provide detailed inspection data, which can be used to track trends, identify issues, and make better decisions. This helps in improving the overall manufacturing process.

How Vision Inspection Systems Work

A typical vision inspection system includes the following components:

- Cameras – Capture high-resolution images of the product.

- Lighting – Ensures proper illumination for clear images.

- Image Processing Software – Analyzes the images using preset rules.

- Controller or PC – Runs the software and handles input/output tasks.

- Rejection Mechanism – Removes defective products automatically.

The system is usually integrated into the production line and is set up to monitor specific features of a product. For example, in a bottle-filling plant, the system may check if the bottle is filled correctly, if the cap is sealed properly, and if the label is in place.

Common Applications in Manufacturing

1. Packaging Inspection

- Vision systems check for proper label placement, barcode readability, correct package sealing, and package integrity.

2. Surface Defect Detection

- Used in industries like electronics and automotive, these systems detect scratches, dents, cracks, and contamination on surfaces.

3. Assembly Verification

- Ensures that all parts are assembled correctly. For example, in electronics, it can verify the presence and position of components on a PCB.

4. Dimensional Measurement

- Measures length, width, height, and alignment to confirm that parts meet required specifications.

5. OCR and Barcode Reading

- Reads text, serial numbers, and barcodes for product tracking and traceability.

6. Color and Pattern Matching

- Checks color accuracy and verifies patterns, which is crucial in printing and textile industries.

Industries That Use Vision Inspection Systems

Vision inspection systems are used across a wide range of industries, including:

- Automotive – For checking engine parts, body panels, and safety components.

- Pharmaceutical – For inspecting pills, bottles, blister packs, and labels.

- Food and Beverage – To ensure packaging is sealed, filled, and labeled correctly.

- Electronics – For PCB inspection, solder joint analysis, and component verification.

- Plastic and Rubber – For detecting defects in molded parts.

- Textiles – For color matching and defect detection in fabrics.

Choosing the Right Vision Inspection System

When selecting a vision system for your factory, consider the following:

1. Inspection Requirements

- What do you need to inspect—size, color, shape, label, or surface? Define your inspection criteria clearly.

2. Speed and Resolution

- Choose a system that can match the speed of your production line without compromising on image quality.

3. Lighting and Environment

- The right lighting setup is critical. Choose lighting based on product material, surface finish, and inspection angle.

4. Software Flexibility

- Ensure the software can be easily updated or customized to meet changing inspection needs.

5. Ease of Integration

- Pick a system that can be integrated into your existing production line and IT systems.

Future Trends in Vision Inspection Systems

Technology in vision inspection is evolving rapidly. Here are some trends shaping the future:

1. AI and Machine Learning

- Modern systems are using AI to learn and adapt over time. This improves detection accuracy, especially in complex scenarios where traditional rules may not work.

2. 3D Vision Inspection

- 3D cameras and sensors allow the system to inspect height, depth, and volume. This is useful in applications like automotive, casting, and assembly verification.

3. Cloud Integration

- Some systems send data to the cloud for advanced analytics, remote monitoring, and predictive maintenance.

4. Edge Computing

- With edge devices, image processing can happen on the machine itself, reducing latency and improving response times.

5. Multi-Camera Systems

- Advanced setups use multiple cameras for inspecting from different angles, covering blind spots and complex geometries.

Overall, vision inspection systems are a Breakthrough for manufacturers aiming to boost productivity, reduce defects, and ensure top-notch quality. They offer real-time, reliable, and repeatable inspection without slowing down the production line. Whether you're making cars, chips, or circuit boards, integrating a vision system helps you stay ahead of the competition by making your production smarter, faster, and more cost-efficient. If you’re ready to upgrade your factory and reduce human error, investing in a vision inspection system is a smart choice. With flexible setups, advanced AI, and proven ROI, these systems are no longer a luxury—they’re a necessity for modern manufacturing.