Industrial automation systems depend heavily on stable and efficient power. From PLC panels and control cabinets to sensors, drives, and communication equipment, every component needs a reliable electrical supply to function correctly. One critical component that often works silently behind the scenes is the toroidal power transformer.

In recent years, energy efficiency has become a key requirement in industrial automation. Rising energy costs, stricter regulations, and the demand for sustainable operations have pushed industries to adopt smarter power solutions. This is where energy-efficient toroidal transformers play an important role.

This blog explains what a toroidal power transformer is, why it is energy efficient, and how it benefits modern industrial automation systems.

Role of Power Transformers in Industrial Automation

A power transformer is used to step voltage up or down to suitable levels for equipment operation. In industrial automation, transformers supply power to:

- PLCs and I/O modules

- HMI panels

- Control relays and contactors

- Sensors and transmitters

- Industrial communication devices

The quality of power delivered directly affects system reliability, accuracy, and safety. Traditional transformers have been widely used for decades, but they also come with energy losses, noise, and heat generation.

To overcome these challenges, industries are increasingly choosing toroidal designs.

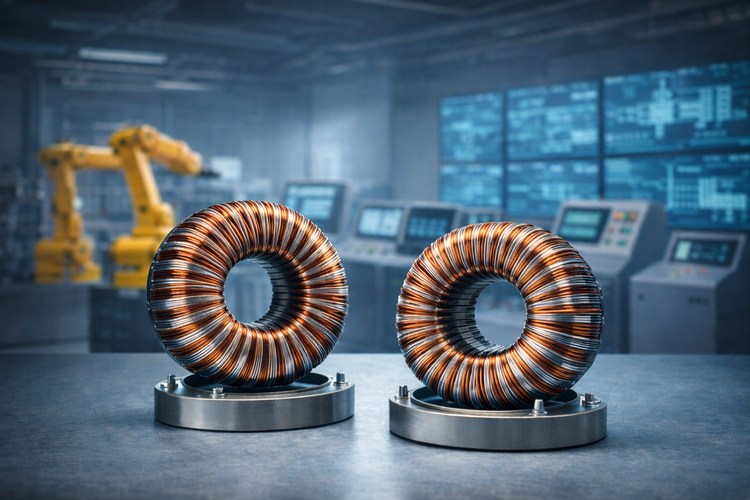

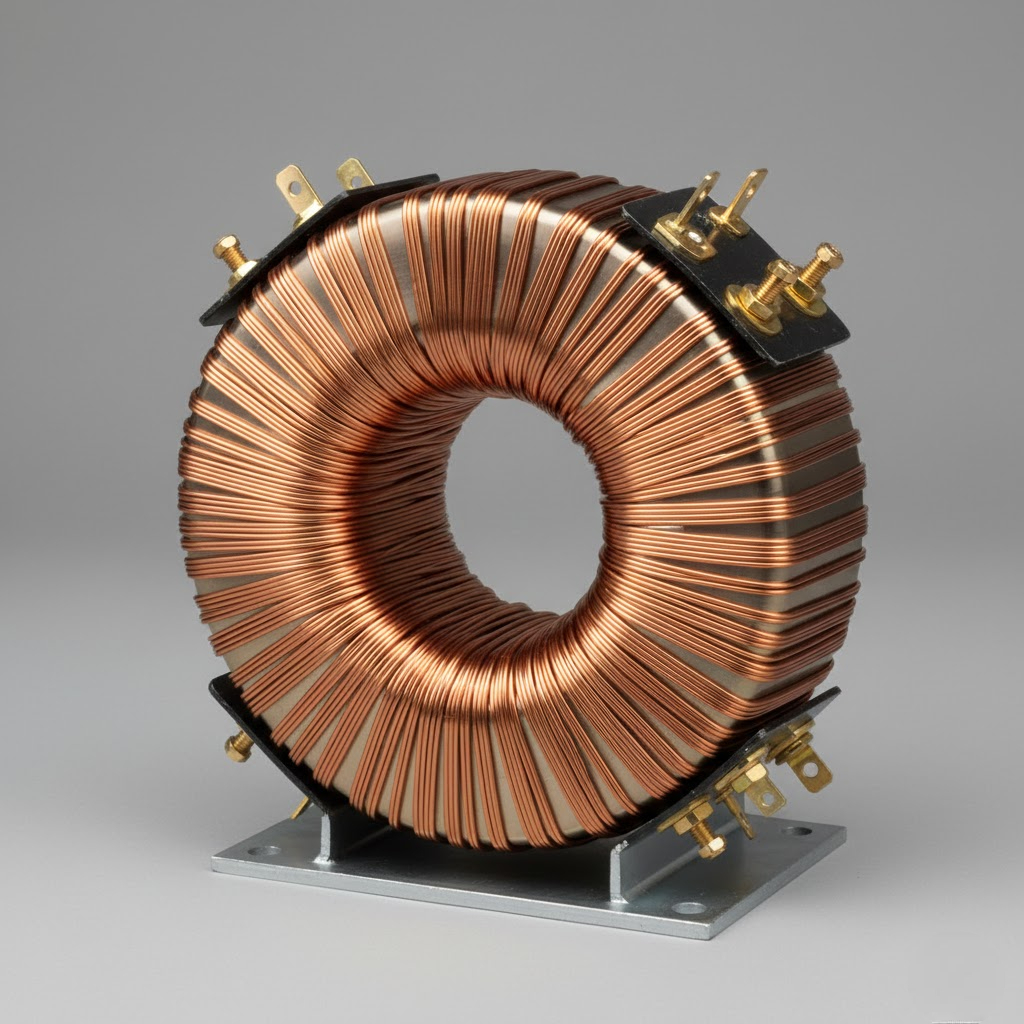

What Is a Toroidal Power Transformer?

A toroidal power transformer uses a donut-shaped (toroidal) magnetic core instead of the rectangular laminated core found in conventional transformers. Copper windings are evenly distributed around this circular core.

This unique shape allows the magnetic flux to remain tightly contained within the core, which improves performance and efficiency. Toroidal transformers are commonly used in applications where energy efficiency, low noise, and compact size are important making them ideal for industrial automation.

Why Energy Efficiency Matters in Automation Systems

Energy efficiency is no longer optional in modern industries. Automation systems often run continuously, sometimes 24/7, and even small power losses can add up to significant costs over time.

Energy-efficient components help industries:

- Reduce electricity consumption.

- Lower operational costs

- Minimize heat generation.

- Improve equipment lifespan.

- Meet energy efficiency standards.

Using efficient transformers is a simple yet effective way to optimize overall system performance.

How Toroidal Transformers Achieve High Energy Efficiency

The design of a toroidal power transformer naturally supports energy savings. Below are the key reasons why it is more efficient than traditional transformers.

1. Lower Core Losses

The continuous circular core reduces magnetic flux leakage. As a result, less energy is wasted as heat, and more power is transferred efficiently to the load.

2. Reduced Copper Losses

Shorter winding lengths mean lower resistance in the copper windings. This helps reduce energy losses during power transmission.

3. Minimal No-Load Losses

Even when not fully loaded, toroidal transformers consume very little energy compared to conventional designs. This is especially useful in automation panels that operate under varying loads.

Compact Design for Space-Saving Panels

Space is always a concern in industrial control panels. Toroidal transformers are smaller and lighter than traditional transformers with the same power rating.

Their compact size allows:

- Better panel layout

- Improved airflow

- Easy integration into tight spaces

This makes them ideal for modern automation systems where panel miniaturization is a priority.

Low Heat Generation and Improved Safety

Excessive heat can damage sensitive automation equipment. Since toroidal transformers operate more efficiently, they generate less heat.

Benefits of low heat generation include:

- Enhanced safety inside control cabinets

- Reduced need for cooling systems

- Longer life of surrounding components

This contributes to stable and long-lasting automation systems.

Reduced Electrical Noise and Interference

Industrial environments often have multiple electronic devices operating simultaneously. Electrical noise can interfere with control signals and communication networks.

A toroidal power transformer produces very low electromagnetic interference (EMI) due to its closed magnetic path. This helps protect sensitive automation equipment such as:

- PLC CPUs

- Analog signal modules

- Communication interfaces

- Cleaner power means more accurate control and fewer system errors.

Silent Operation in Industrial Settings

Noise may not seem critical in heavy industries, but silent operation becomes important in control rooms, laboratories, and clean environments.

Toroidal transformers operate with minimal humming or vibration, making them suitable for:

- Control rooms

- Process monitoring systems

- Automation labs

This improves workplace comfort and system reliability.

High Reliability for Continuous Operation

Industrial automation systems often run continuously without shutdowns. Components must be reliable and durable.

- Toroidal transformers are known for:

- Strong mechanical stability

- Uniform magnetic field distribution

- Long service life

This reliability reduces downtime and maintenance costs.

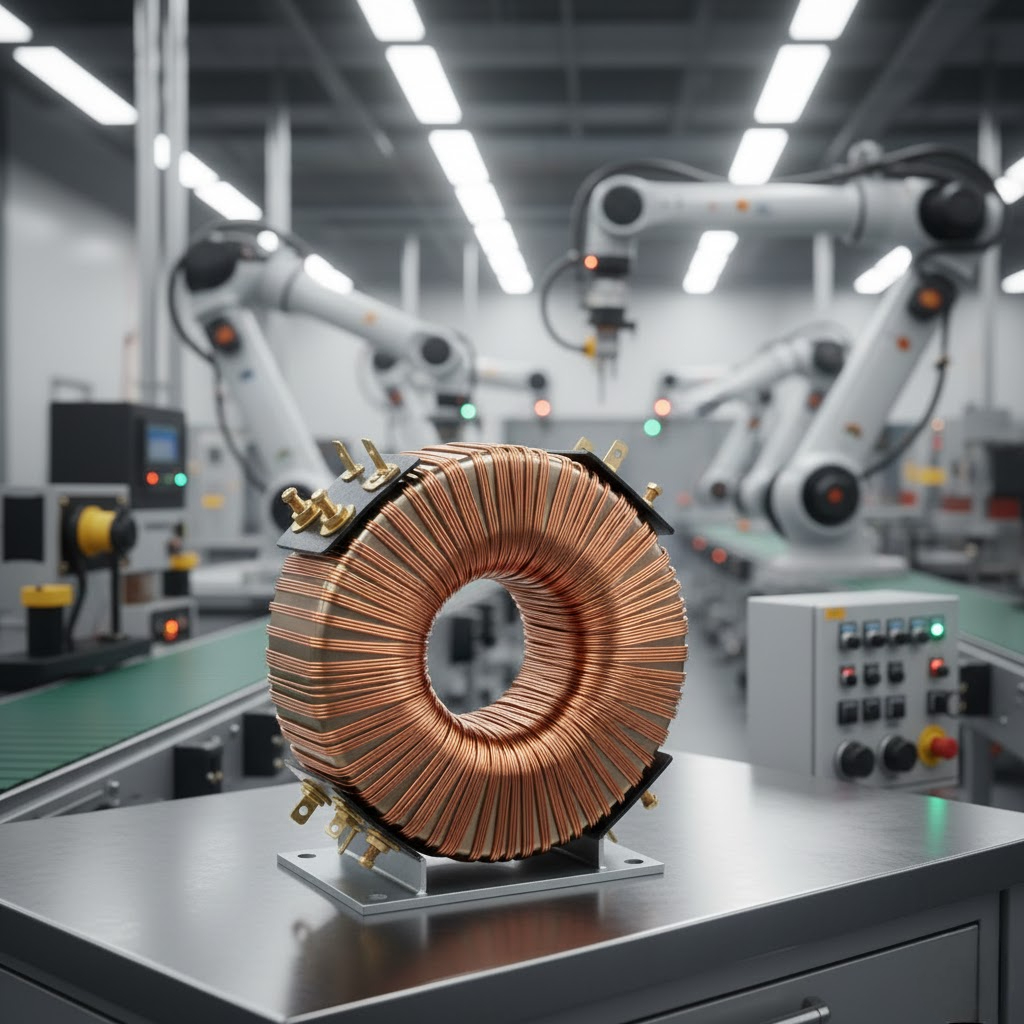

Applications of Toroidal Power Transformers in Industrial Automation

The toroidal power transformer is widely used across different automation applications, including:

1. Control Panels

- Used to supply stable voltage to PLCs, relays, and I/O modules.

2. Industrial Machinery

- Supports power requirements for automation electronics in machines.

3. Instrumentation Systems

- Ensures accurate power delivery to sensors and transmitters.

4. Robotics and Motion Control

- Provides clean power for controllers and feedback devices.

5. Power Distribution Units

- Used in compact power supplies within automation cabinets.

Supporting Sustainable and Green Automation

Sustainability is becoming a major focus in industrial operations. Energy-efficient transformers contribute directly to green automation initiatives.

Advantages include:

- Lower carbon footprint

- Reduced energy waste

- Compliance with efficiency standards

By choosing toroidal transformers, industries move closer to sustainable manufacturing goals.

Comparing Toroidal and Traditional Transformers

While traditional transformers are still used, toroidal designs offer clear advantages:

- Higher energy efficiency

- Smaller size and lighter weight

- Lower noise and EMI

- Better thermal performance

These benefits make toroidal transformers a smart upgrade for modern automation systems.

Choosing the Right Toroidal Transformer

When selecting a toroidal power transformer for industrial automation, consider:

- Voltage and current requirements

- Environmental conditions

- Mounting space

- Compliance with industry standards

Choosing the right specification ensures maximum efficiency and system reliability.

Role in Modern Smart Factories

Smart factories rely on efficient, connected, and reliable power systems. Toroidal transformers support this vision by delivering stable power with minimal losses.

Their use aligns perfectly with Industry 4.0 principles, where efficiency and reliability are key performance indicators.

The toroidal power transformer is a smart and energy-efficient solution for modern industrial automation systems. Its compact design, low energy losses, reduced noise, and high reliability make it an excellent choice for control panels, machinery, and instrumentation.

As industries focus more on energy efficiency, sustainability, and system performance, toroidal transformers continue to gain importance. Investing in energy-efficient power components today helps build automation systems that are reliable, cost-effective, and future-ready.

By choosing toroidal transformers, industrial automation moves one step closer to smarter, greener, and more efficient operations.