In today’s fast-paced world, the demand for mobile phones is rise steeply. To meet this growing need, manufacturers are turning to automation. Automation not only speeds up production but also improves precision and reduces human error. Companies like Apple and Samsung depend on automated systems to maintain consistency, quality, and efficiency in their manufacturing units.

In this blog, we will explore the essential automation components used in mobile manufacturing: PLCs, HMIs, Servo Motors, and Sensors.

1. Programmable Logic Controllers (PLCs)

PLCs, or Programmable Logic Controllers, are industrial computers designed to control and automate manufacturing processes. They receive inputs from sensors, process the information, and trigger the appropriate outputs, such as starting or stopping machinery.

Role of PLCs in Mobile Manufacturing:

PLCs are the backbone of mobile manufacturing automation. In mobile phone factories, PLCs manage assembly lines, coordinate robotic arms, and ensure each process is completed in the right sequence. From placing microchips to screwing in tiny components, PLCs make it all happen seamlessly.

Real-Life Example: At Samsung's smartphone manufacturing plants, PLCs control every step of the process, including soldering components to circuit boards and checking battery placement. These controllers help maintain a high output with minimal errors.

Benefits:

- High-speed operation

- Consistent performance

- Easy to program and modify

- Supports complex logic operations

2. Human-Machine Interfaces (HMIs)

An HMI, or Human-Machine Interface, is the dashboard or screen that allows humans to interact with machines. It displays data collected from the PLC and allows operators to monitor, control, and troubleshoot the system.

Role of HMIs in Mobile Manufacturing

HMIs in mobile factories are used to oversee production status, error logs, and machine diagnostics. Operators can use HMIs to make quick changes to the production process, track performance, and resolve issues in real-time.

Real-Life Example: Apple’s assembly lines are known for using sophisticated HMI systems that allow operators to manage hundreds of machines through intuitive touchscreens. For instance, if a robot arm misplaces a component, the HMI displays a warning so the issue can be corrected instantly.

Benefits:

- Real-time monitoring

- User-friendly interface

- Enhances safety and efficiency

- Quick decision-making

3. Servo Motors

Servo motors are precision motors used to control movement and positioning in automated systems. They receive signals from the PLC and adjust their rotation or movement based on commands.

Role of Servo Motors in Mobile Manufacturing

Servo motors are essential in tasks that require accuracy, such as aligning screens, placing cameras, or assembling delicate internal components. In mobile production, where even a millimeter can make a difference, servo motors are critical.

Real-Life Example: In Apple’s iPhone production, servo motors control robotic arms that place camera modules into their slots. These motors ensure each piece fits perfectly without causing damage to sensitive parts.

Benefits:

- High precision

- Controlled speed and torque

- Low noise and vibration

- Efficient energy use

4. Sensors

Sensors are devices that detect physical properties like temperature, pressure, proximity, or motion and send this data to the PLC for processing.

Role of Sensors in Mobile Manufacturing

Sensors play a vital role in quality control and safety. For example, proximity sensors detect whether a phone screen is correctly placed, and temperature sensors monitor heating elements used in soldering. Without sensors, detecting errors early in the process would be almost impossible.

Real-Life Example: Samsung uses a wide range of sensors in its factories to ensure that each component is in the right place and meets quality standards. Proximity sensors ensure screws are correctly inserted, while vision sensors check for defects on the display.

Benefits:

- Accurate and quick feedback

- Enhances product quality

- Prevents equipment damage

- Supports real-time decision making

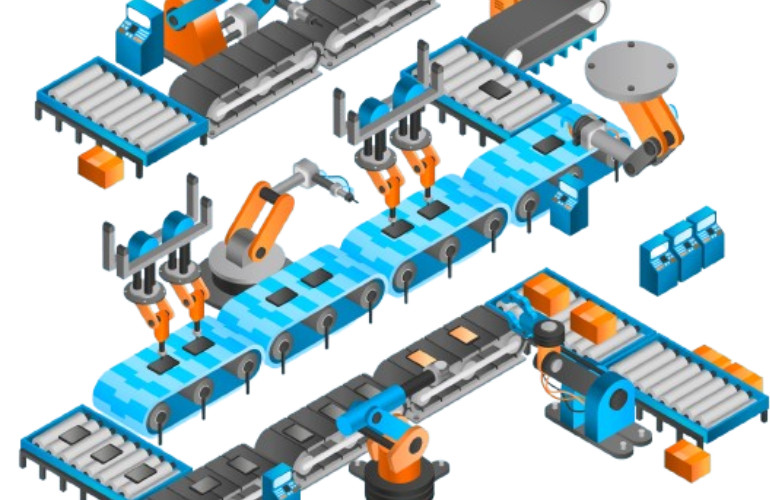

How These Components Work Together

The real power of automation lies in how these components work together. Here’s a simplified flow:

- Sensors detect an action, like the placement of a mobile screen.

- The PLC processes this input and send commands to machines or servo motors.

- If something goes wrong, the HMI alerts the operator.

- The operator takes necessary actions or lets the automated system correct the issue.

This loop ensures the production line runs smoothly, efficiently, and with minimal manual intervention.

Advantages of Automation in Mobile Manufacturing

- Higher Productivity: Machines can operate continuously, increasing output.

- Improved Quality: Reduced human error leads to better consistency and fewer defects.

- Lower Costs: Once installed, automated systems can reduce long-term labor and operational costs.

- Safety: Reduces human involvement in potentially dangerous tasks.

- Flexibility: Easy to reprogram for new models or changes in design.

Automation is essential in mobile manufacturing. Components like PLCs, HMIs, servo motors, and sensors work in accord to build smartphones with precision and speed. Companies like Apple and Samsung have demonstrated how integrating these technologies leads to high-quality products and efficient production lines. As mobile technology evolves, the role of automation will only grow, making these components more crucial than ever. Whether you're setting up a new production unit or upgrading an existing one, investing in the right automation components is a smart move toward future-proofing your business.