In the world of industrial automation, transistors play a quiet yet vital role. These small semiconductor devices form the backbone of modern control systems that power industries, factories, and manufacturing units across the globe. Whether it’s managing motor speed, regulating power, or processing signals, transistors make control systems efficient, reliable, and intelligent.

This blog explores how transistors revolutionized industrial control, their types, their functions, and why they remain crucial in today’s technology-driven industrial landscape.

What is a Transistor?

A transistor is a tiny semiconductor device that can amplify, control, or switch electrical signals and power. It acts as a gatekeeper that determines how much current or voltage flows in a circuit. Made primarily from silicon or germanium, transistors are the building blocks of almost every electronic device — from computers to control panels.

In industrial control systems, transistors help manage complex operations by ensuring accurate signal processing, reliable power distribution, and smooth automation functions.

Role of Transistors in Industrial Control Systems

Industrial control systems (ICS) are responsible for monitoring and managing processes like temperature, pressure, flow, and motion in industrial environments. Transistors ensure that these systems respond quickly and accurately to changing conditions. Let’s look at how they contribute to different parts of industrial control.

a) Signal Amplification

Many sensors and devices produce weak signals that need amplification before being processed. Transistors act as amplifiers that increase signal strength without distorting it, ensuring precise control and communication across the system.

b) Switching Operations

Transistors can turn electrical circuits on or off rapidly, making them essential in switching power circuits, motor starters, and relay control. Their high-speed switching capability supports automation processes that require millisecond accuracy.

c) Power Regulation

In control systems, power stability is critical. Transistors regulate voltage and current flow, protecting devices from fluctuations. They are widely used in power supply units, DC-DC converters, and motor control systems to maintain consistent operation.

d) Logic Control

Transistors form the foundation of digital logic. In microcontrollers and PLCs, millions of transistors work together to execute logic operations, enabling automation systems to make intelligent decisions based on input data.

Types of Transistors Used in Industrial Control

Different types of transistors are used depending on the application and power requirement. The three most common types are BJT, MOSFET, and IGBT.

a) Bipolar Junction Transistor (BJT)

A BJT is one of the earliest types of transistors. It works by controlling current flow between two terminals using a third terminal called the base. BJTs are ideal for low-frequency amplification and switching in small control circuits.

Applications:

- Signal amplifiers

- Motor control circuits

- Low-power switching devices

b) Metal-Oxide-Semiconductor Field-Effect Transistor (MOSFET)

MOSFETs are voltage-controlled devices that are faster and more energy-efficient than BJTs. They are widely used in industrial automation for controlling high-speed switching and power regulation.

Applications:

- DC motor drives

- Power inverters

- Switching regulators

c) Insulated Gate Bipolar Transistor (IGBT)

IGBTs combine the efficiency of MOSFETs with the high-current handling capacity of BJTs. They are used in high-power industrial applications where reliability and performance are critical.

Applications:

- Variable Frequency Drives (VFDs)

- Power converters

- Industrial robots and automation systems

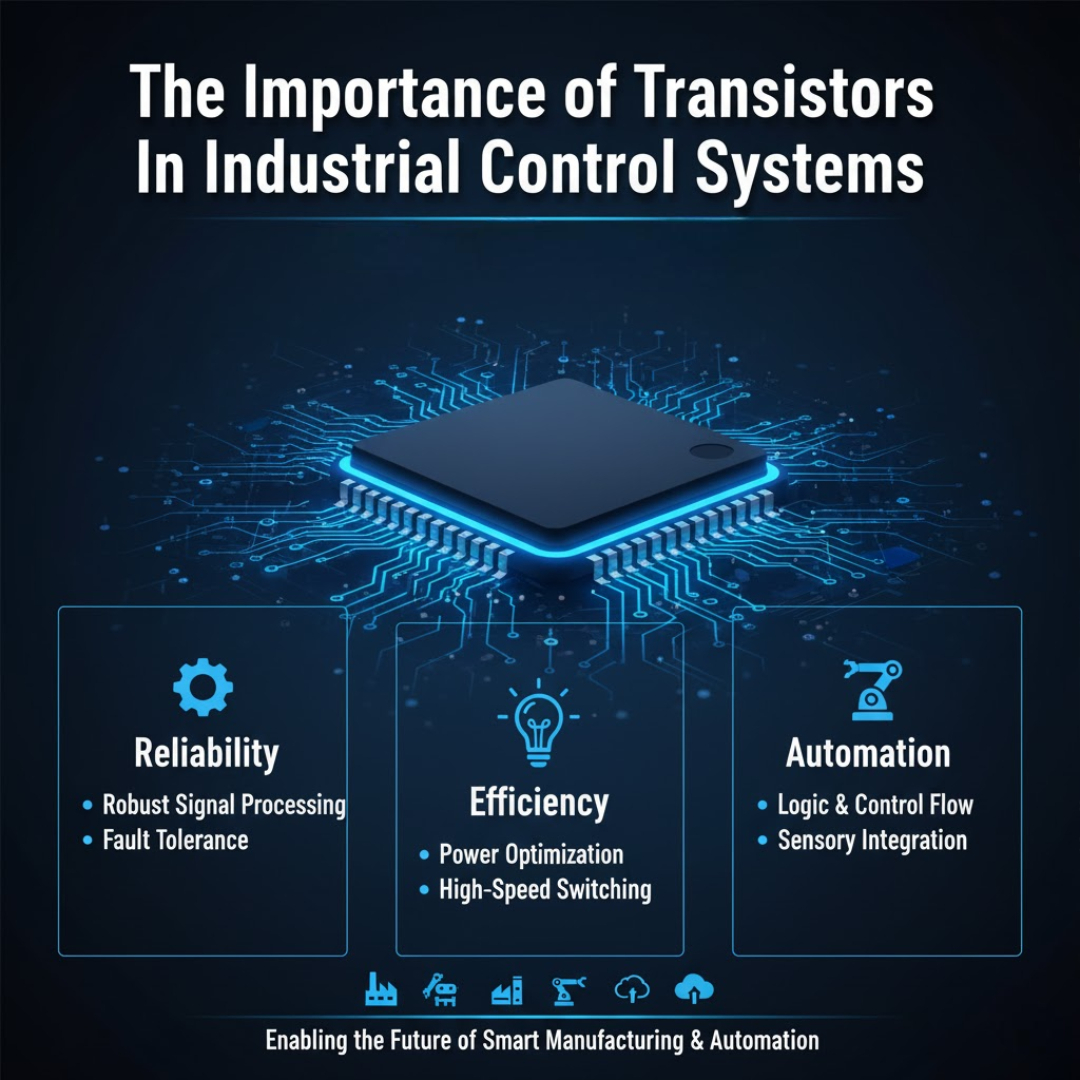

Advantages of Using Transistors in Industrial Systems

Transistors offer several advantages that make them an essential part of control systems. Here are the key benefits:

a) Compact Size: Transistors are extremely small, allowing modern control systems to be compact and space-saving. This miniaturization has enabled industries to design portable and modular control panels.

b) Energy Efficiency: Transistors consume less power compared to older technologies like vacuum tubes or mechanical relays. This helps reduce operational costs and energy wastage.

c) Reliability: Transistors have no moving parts, which means less wear and tear. They can function for years without failure, even in harsh industrial conditions.

d) High-Speed Switching: Transistors can switch on and off in microseconds, making them perfect for processes that require fast response times, such as motor control and automation signaling.

e) Improved Control Accuracy: Transistors enable precise voltage and current regulation, resulting in accurate control of industrial processes such as temperature management, speed regulation, and pressure control.

Applications of Transistors in Industrial Control Systems

Transistors are integrated into almost every part of an industrial control system. Some of the major applications include:

a) Motor Control: Transistors regulate voltage and current to control the speed and torque of motors. In devices like Variable Frequency Drives (VFDs), transistors are responsible for converting DC power to variable AC output, enabling smooth speed control.

b) Power Conversion: In power converters and inverters, transistors handle switching functions that transform electrical energy from one form to another efficiently.

c) Signal Conditioning: Many industrial sensors send weak analog signals. Transistor-based amplifiers boost these signals before they are processed by the control system.

d) Automation and Robotics: Transistors play a key role in PLCs, robotic arms, and servo systems, ensuring fast, accurate, and safe operation of automated machinery.

e) Protection Systems: Transistors are also used in safety circuits and overcurrent protection devices to shut down systems instantly during electrical faults.

Transistors and Modern Industrial Automation

The rise of Industry 4.0 and smart manufacturing has pushed transistors to even greater importance. With growing use of sensors, controllers, and communication systems, the demand for reliable transistor-based control is higher than ever.

In IoT-enabled factories, transistors support microcontrollers and processors that handle real-time monitoring and decision-making. They also improve the performance of machine learning-based predictive maintenance systems, ensuring equipment uptime and reducing breakdowns.

Transistor technology has advanced to include power transistors, nanotransistors, and compound semiconductors, offering higher efficiency, greater speed, and improved thermal stability.

Challenges and Future of Transistors in Industrial Control

Despite their reliability, transistors face challenges in extreme industrial environments such as high temperatures, vibration, or voltage surges. However, ongoing innovation in semiconductor materials like silicon carbide (SiC) and gallium nitride (GaN) is overcoming these limitations.

The future of industrial transistors will focus on:

- Greater energy efficiency

- Higher power density

- Integration with AI-based control systems

- Enhanced durability for harsh environments

As industries move toward green manufacturing and smart automation, transistors will continue to evolve as key components in sustainable, intelligent control systems.

Why Transistors Are Crucial in Industrial Automation

Without transistors, the automation revolution would not have been possible. Their ability to process, switch, and regulate electrical signals makes them the foundation of industrial electronics. Every programmable controller, sensor, drive, or communication module relies on the precise performance of transistors.

From reducing energy costs to enabling predictive control, transistors ensure that industrial systems run efficiently, safely, and reliably. Their role is not just technical—it’s strategic, shaping the future of industrial progress.

Transistors may be small, but their impact on industrial control systems is enormous. They enable industries to automate complex processes, improve accuracy, save energy, and enhance safety. As technology continues to evolve, transistors will remain central to innovation in industrial automation.

From early vacuum tube replacements to today’s high-performance IGBTs and MOSFETs, transistors have driven decades of industrial advancement. In every control circuit, drive, and automated machine, these small components ensure seamless operation and control — proving that even the smallest parts can make the biggest difference.